Running a warehouse comes with constant risks—from heavy forklift traffic to crowded aisles and fast-moving operations. Without clear directions and safety systems, employees may face accidents, misplaced inventory, or even costly compliance violations. The lack of warehouse signage and line striping often leaves teams guessing, which slows productivity and creates unsafe working conditions.

The solution is simple but powerful: invest in clear signage and durable line striping. These two tools form the foundation of a safe and efficient warehouse. With the right systems in place, you protect your staff while improving workflow, compliance, and long-term efficiency. In this article, we’ll cover the best tips for using warehouse signage and line striping to transform safety and performance in your facility.

Table of Contents

- Warehouse Signage in Safety and Compliance

- Best Practices for Line Striping in Warehouses

- Integrating Signage and Line Striping for Maximum Impact

- Maintenance and Inspection Tips

- Cost-Effective Strategies for Implementation

- Building Safer, Smarter Warehouses with Signage and Line Striping

- Quick FAQs About Warehouse Signage and Line Striping

Warehouse Signage in Safety and Compliance

Warehouse signage plays a vital role in guiding employees, preventing accidents, and keeping operations compliant with safety standards. Proper signs remove confusion, giving clear directions for where to go, what to do, and which hazards to avoid. This level of organization helps reduce accidents and keeps daily tasks moving without interruptions.

In addition, signage is directly tied to OSHA and ANSI regulations. Businesses that neglect proper signs risk facing penalties or shutdowns. Investing in the right signage ensures your facility meets compliance standards while creating a safer environment for workers, contractors, and visitors alike.

RELATED: How Can a Strategic Warehouse Signage Transform Your Operations?

Why Clear Signage Matters for Accident Prevention

Clear signage minimizes risk by delivering instant, easy-to-understand instructions. From stop signs at forklift intersections to hazard warnings near chemical storage, visual cues prevent workers from making dangerous mistakes. By using large fonts, bold colors, and consistent placement, signage becomes an everyday safety net for everyone in the warehouse.

Regulatory Compliance and OSHA Standards

OSHA requires workplaces to post clear warning and instructional signs. These rules exist to prevent injuries and protect lives. Compliance ensures your team knows where fire exits, emergency equipment, and restricted areas are located. Staying up to code also avoids fines and supports a culture of responsibility.

Types of Signs Every Warehouse Should Have

Every warehouse relies on various signs to create a safe, organized, and compliant work environment. Safety warning signs protect employees from common hazards like forklifts or electrical equipment. Directional signs, on the other hand, keep people moving smoothly by pointing out exits, aisles, and loading docks. Hazard communication signs provide clear instructions about chemicals, flammable items, or restricted zones, helping prevent accidents and misunderstandings.

- Use pictograms along with words so employees who speak different languages can still understand.

- Position signs at eye-level or higher to ensure maximum visibility across busy work zones.

- Opt for reflective or illuminated signs in areas with poor lighting or around night-shift operations.

Best Practices for Line Striping in Warehouses

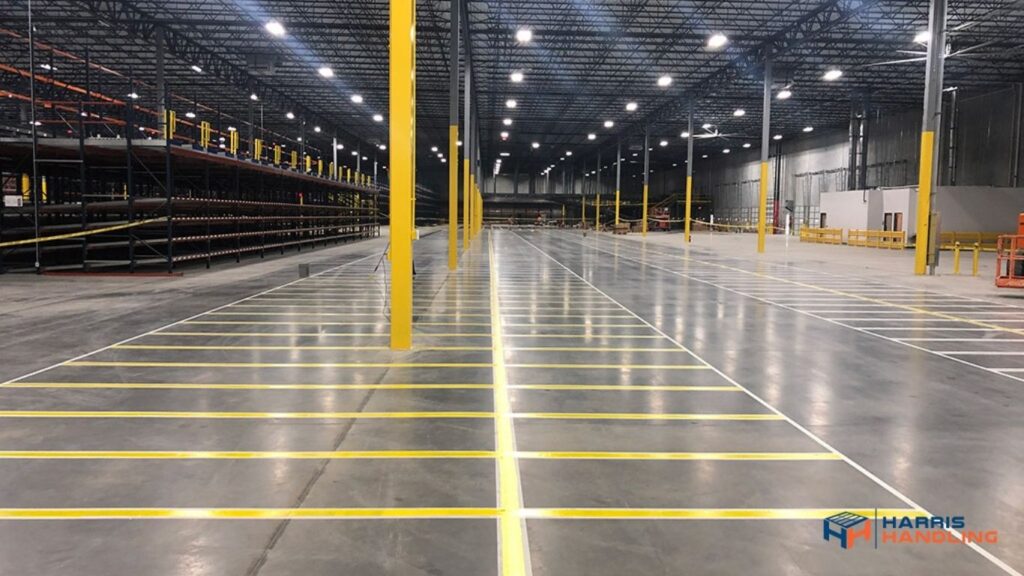

Line striping creates a visual map of your warehouse floor. These markings separate people from machines, organize traffic, and designate areas for storage. Without them, spaces quickly become chaotic, leading to accidents and inefficiencies. Clear striping ensures smooth flow and order across busy operations.

However, not all line striping is created equal. Warehouses must choose the right materials, colors, and placement to maximize durability and clarity. Faded or poorly applied striping can cause confusion and increase safety risks, which is why maintenance and material choice are critical.

The Purpose of Line Striping for Workflow Efficiency

Line striping directs foot traffic, forklift routes, and designated storage areas. When employees can see where to walk or where machines should operate, accidents decline, and productivity increases. A well-marked floor turns confusion into a streamlined system.

Choosing the Right Materials for Durability

Warehouses face heavy wear and tear, so choosing durable paint or tape is essential. Paint lasts longer in high-traffic zones but may require downtime during application. Tape is faster to install and replace but less durable under constant forklift use. Selecting the right option depends on traffic, load type, and maintenance needs.

Line Striping Color Codes and Their Meanings

Color-coded floor markings are critical for maintaining both safety and efficiency in a warehouse. Each color carries a universal meaning that employees quickly learn to recognize, creating a visual language across the facility. Yellow is commonly used to mark pathways and aisles, ensuring workers and forklifts stay within safe routes. Red identifies fire safety equipment and emergency zones, signaling areas that must remain clear at all times. Blue and green often designate storage spaces or safety zones, giving staff clear boundaries for organization.

- Introduce color charts during training sessions so new employees understand striping standards from day one.

- Use contrasting borders or double lines in high-risk areas to increase awareness and visibility.

- Regularly audit color use to ensure consistency and prevent overlapping meanings across departments.

Integrating Signage and Line Striping for Maximum Impact

When combined, signage and line striping form a complete visual safety system. Striping organizes traffic flow on the floor, while signage provides context and instruction. Together, they eliminate confusion and guide staff with both directional and informational cues. This combination improves efficiency while minimizing risks.

Yet, effectiveness depends on smart placement and upkeep. Overcrowding with too many signs or letting striping fade creates more confusion than clarity. By designing a unified strategy, warehouses can create a safer, more productive environment.

Creating a Unified Visual Safety System

Signs provide written or pictorial instructions, while floor markings guide movement and boundaries. When they work together, employees don’t have to guess where to go or what to avoid. For example, a striped walkway paired with a “Pedestrian Only” sign doubles the clarity and reinforces safe behavior. This layered approach reduces mistakes, speeds up training for new staff, and keeps everyone on the same page every day.

Strategic Placement for High-Visibility

The best safety system is useless if people can’t see it. Signs should be installed at natural eye level and placed at decision points, like intersections or near machinery, where quick action is needed. Floor striping should cover high-traffic areas, workstations, and pathways to separate people from equipment. Warehouses should also consider lighting, line of sight, and employee routines when deciding where markings go.

Common Mistakes to Avoid in Implementation

One common error is cluttering areas with too many signs, which overwhelms employees instead of helping them. Another issue is inconsistent use of colors, shapes, or wording—confusion grows when staff can’t rely on a single standard. Lastly, many facilities fail to refresh faded lines or damaged signs, leading workers to ignore them over time. Avoiding these pitfalls requires planning, consistency, and routine upkeep.

Maintenance and Inspection Tips

No matter how well-designed, signage and striping wear down over time. Regular inspections are critical to keep safety systems working as intended. Faded signs or peeling lines reduce visibility and increase accidents. By scheduling consistent checks, warehouses ensure compliance and reliability.

Beyond safety, maintenance also preserves efficiency. Clear systems keep workflows steady and prevent costly disruptions caused by accidents or confusion. Proactive care ensures your investment delivers long-term results.

How Often to Inspect Warehouse Signage

Signs should be checked at least once a month to make sure they’re still visible, accurate, and in the right location. Warehouses with heavy traffic may need inspections even more frequently. During these checks, managers should look for fading, damage, or blocked signs. It’s also smart to confirm that messages are still relevant after layout changes or new equipment installations. Regular inspections keep safety consistent and show employees that management takes their well-being seriously.

Maintaining Line Striping for Longevity

Line striping takes a beating every day from forklifts, pallets, and foot traffic. Without care, markings can fade fast, losing their effectiveness and creating confusion. To extend their life, floors should be cleaned regularly to prevent dirt and debris from eroding paint or tape. Touch-ups should be scheduled before striping becomes unreadable, keeping guidance consistent for employees. For long-term success, warehouses should also choose materials that fit their environment, like heavy-duty epoxy for high-traffic areas.

When to Upgrade or Replace Safety Markings

Faded colors, chipped paint, and broken signs are signs it’s time for a replacement. Upgrades are also necessary when warehouse layouts change, such as adding new storage areas or rerouting traffic patterns. Ignoring worn-out safety systems can lead to accidents, compliance issues, and lower employee trust. By replacing markings and signs before they fail, you keep your warehouse safe and efficient. Think of it as an investment that protects both your people and your bottom line.

Cost-Effective Strategies for Implementation

Improving warehouse safety doesn’t have to drain budgets. By planning carefully and prioritizing high-risk areas first, managers can implement effective systems without overspending. Even modest upgrades to signage and striping can drastically improve safety and efficiency.

In addition, warehouses can decide between professional installation or in-house solutions. Each comes with advantages, and choosing the right approach depends on budget, labor resources, and long-term goals.

Budgeting for Safety Improvements

Warehouses should allocate funds toward high-priority areas like pedestrian walkways, hazardous zones, and emergency exits. Starting small and expanding as budgets allow ensures safety improvements are ongoing and affordable.

DIY vs. Professional Installation

DIY projects may save money upfront, but professionals bring expertise and compliance knowledge. Professional installation ensures materials are applied correctly and systems meet OSHA standards, reducing long-term risks and costs.

Long-Term ROI of Proper Signage and Striping

Clear signage and durable line striping provide measurable returns by reducing accidents, lowering insurance costs, and improving productivity. These benefits far outweigh initial costs, making them one of the smartest safety investments for any facility.

Building Safer, Smarter Warehouses with Signage and Line Striping

Warehouse signage and line striping are more than just visual cues. It’s about creating a space where every worker, visitor, and piece of equipment knows exactly where to go, what to do, and how to avoid danger. With the right signage and line striping systems in place, you reduce confusion, lower risks, and improve productivity. When safety and efficiency work together, the whole operation runs smoother.

Using visual cues—clear signs, bright stripes, and consistent color codes—helps protect against common hazards like forklift collisions, blocked emergency exits, or traffic missteps. From OSHA compliance to daily workflow improvements, the right signs and markings deliver consistent value. Regular inspections, smart budgeting, and professional installation ensure your systems stay reliable over the long term. The payoff is fewer injuries, smoother operations, and higher employee confidence in their workplace. It also shows your team that you care: that their well-being matters. Over time, that builds trust, reduces accidents, and even cuts down costs tied to downtime or compliance issues.

Take the first step—a safer, more efficient warehouse begins now with Harris Handling.

Don’t wait for a near-miss or safety citation to push you into action. Whether you need high-visibility floor markings, OSHA-compliant signs, or expert guidance to plan your safety layout, Harris Handling has over 20 years of experience delivering tailored warehouse storage and materials-handling solutions. We understand what your space needs, the risks you face, and how to deliver quality without breaking your budget.

Contact Harris Handling now to schedule a walk-through, request a signage and striping plan, or get a quote. Let us help you build the warehouse you—and your team—deserve.

🌐 Get Started with a quote today.

📞 Talk to our specialists at 704-661-3501.

Invest in clarity today because safety never takes a day off!

Our Best Sellers:

Quick FAQs About Warehouse Signage and Line Striping:

1. What types of safety signs are required in warehouses?

Every warehouse should have safety warning signs (e.g., forklift traffic, high-voltage areas), directional signs to guide staff and visitors, and hazard communication signs for chemicals or restricted zones. These signs help workers stay safe, meet compliance requirements, and keep workflow smooth.

2. What do warehouse floor marking colors mean?

Color coding in warehouse line striping has specific meanings:

- Yellow marks aisles and safe walking paths.

- Red highlights fire safety zones and emergency equipment.

- Blue or Green identifies storage areas or safety stations.

3. How often should warehouse signage and line striping be inspected?

Experts recommend inspecting signage and floor markings at least once a month. High-traffic warehouses may need weekly checks to spot fading, peeling, or blocked signs. Regular inspections keep your facility compliant, safe, and efficient.

YOU’LL ALSO LIKE: