Ensuring the safety of both employees and products within a warehouse or distribution center is of paramount importance. The presence of heavy machinery, the constant movement of goods, and the storage of hazardous materials create an environment where the risk of accident and injury can be high. The utilization of warehouse safety equipment is essential in mitigating these risks. Harris Handling offers a comprehensive selection of safety products designed to provide a secure working environment in your warehouse, distribution center, or manufacturing plant.

Table of Contents

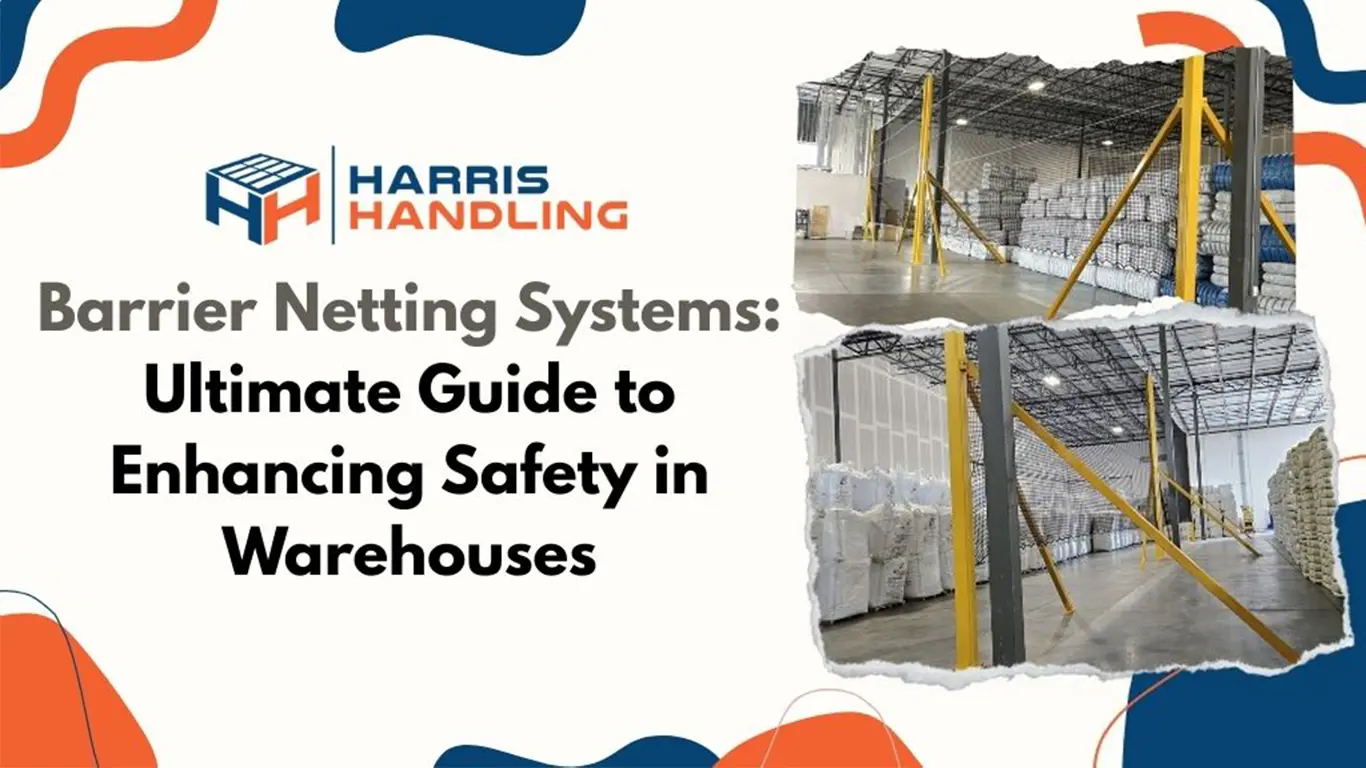

1. Introduction to Barrier Netting Systems

As industries grow and logistics operations become more complex, the need for robust safety measures in industrial environments becomes increasingly important. In warehouses—where the movement of goods and the use of large machinery present constant risks—barrier netting systems serve as essential safety components. These systems are designed to protect personnel, secure merchandise, and reduce the risk of accidents caused by falls or displaced materials.

Barrier netting systems are constructed from high-strength materials capable of withstanding impact from heavy objects, offering durability and long-term performance. They range from lightweight, flexible nets for less demanding uses to heavy-duty versions suited for larger items. Beyond protection, these nets support the organization and efficiency of warehouse operations.

2. The Importance of Barrier Netting in Warehouses

The active environment of a warehouse, marked by frequent movement and the operation of heavy equipment, presents a variety of potential hazards. In such settings, accident prevention is a core responsibility for warehouse management. Barrier netting systems play a central role in supporting this goal, acting as a reliable safeguard against a range of risks.

The primary function of barrier netting is to protect employees. Falling objects from elevated storage areas pose serious threats, and netting systems act as a buffer, helping prevent injuries on the ground. This level of protection contributes to maintaining workplace safety standards and reducing operational interruptions due to accidents.

In addition to personnel safety, these systems help secure stored goods. Racks and shelves often hold valuable inventory that, if not contained, could fall and become damaged. Barrier netting prevents such incidents, helping to preserve inventory and reduce avoidable losses.

3. Harris Handling’s Superior Barrier Netting Solutions

Harris Handling provides a wide selection of barrier netting systems designed to support the varied needs of warehouse operations. The company focuses on delivering solutions that are compatible with each client’s operating conditions, whether the objective is inventory protection, perimeter control, or workspace safety.

Customization and Versatility of Barrier Netting Systems

A key strength of Harris Handling’s offering is its adaptability. Recognizing that warehouse setups differ widely, the company develops solutions that match specific configurations, sizes, and safety priorities. From simple barrier nets to integrated systems, Harris Handling can accommodate a broad range of operational scenarios.

Why Work with Harris Handling

Choosing Harris Handling for your barrier netting system needs comes with numerous advantages:

- Industry Experience: Leveraging years of expertise to deliver the highest quality solutions.

- Adapted Solutions: Tailor-made systems that fit the unique demands of your warehouse.

- Safety-Focused Designs: Products designed to enhance overall workplace safety and productivity.

- Reliable Support: Expert guidance from initial consultation to post-installation services.

4. Getting Started with Harris Handling

Improving warehouse safety and efficiency with Harris Handling is a straightforward process. It begins with an initial consultation, during which the team gathers information about your operations and safety priorities. This discussion forms the basis for a proposal that outlines the most suitable barrier netting solutions for your facility. Based on this, Harris Handling’s experts will devise a tailored proposal, crafting a plan that features the most appropriate barrier netting solutions to meet the demands of your warehouse space.

Once the planning phase is complete, Harris Handling proceeds with an installation process designed to minimize interference with daily operations. The installation team works efficiently to reduce disruptions, aligning project execution with your schedule to maintain business continuity during implementation.

5. Conclusion

In the fast-paced and ever-evolving world of warehouse management, maintaining safety is an ongoing concern. With Harris Handling’s barrier netting systems, businesses can achieve not just a significant enhancement in safety but also improvements in operational efficiency and product protection. With Harris Handling’s solutions, warehouses can reduce risks, protect inventory, and support a safer working environment.

For more information on how to enhance your warehouse with customized barrier netting solutions, visit Harris Handling today.

Contact Information and Free Estimate

For organizations aiming to bolster their warehouse safety, Harris Handling offers personalized consultations to identify the most appropriate safety equipment for each unique setting. Interested parties are invited to reach out for an obligation-free estimate, which is a testament to Harris Handling’s commitment to accessible safety solutions.

To learn more or request a no-obligation estimate, visit the Harris Handling website or contact the team directly at 704-661-3501. Taking this first step contributes to a safer workplace and a stronger overall operation.